| Canard wing

started working on 13-03-06

|

|

|

| 01-07-2007 Nice result |

04-08-2007 Canard is

ready, filled, sanded and elevators adjusted. total weight 7,5 kg.

This gives me a total weight of 198 kg so far! (fuselage + engine +

cowlings +canard + nosecone) |

|

|

| 26-06-2007 Fairing glued to the nose cone

with flox. |

01-07-2007 Nose cone filled

and primed. |

|

|

| 20-06-2007 laminating the fairing on

starboard side. |

26-06-2007 Fairing glued to

the nose cone with flox. |

|

|

| 14-06-2007 6 layers of glass and epoxy. I

had some problems with the wax on the bondo. The epoxy came loose very

difficult. On the other side I pus some adhesive tape on the bondo

replacing the wax. |

14-06-2007 fairing ready for

trimming. (and sanding the bondo off) |

|

|

| 29-05-07 Aligning the elevator hinges, |

14-06-2007 Canard fairing.

First I put some adhesive tape on the surfaces. After that I put the bondo

on with a drainpipe |

|

|

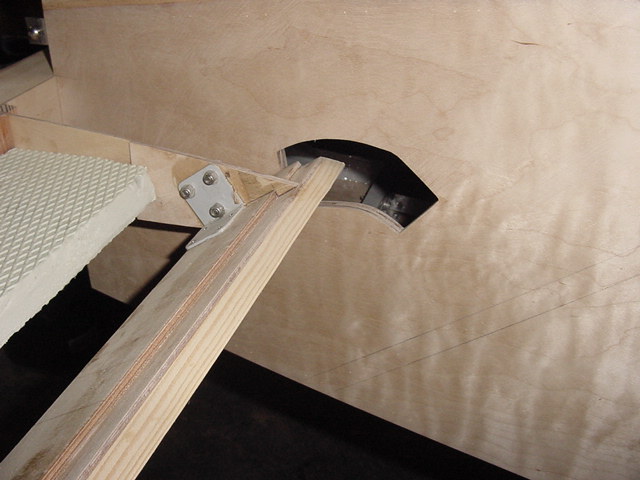

| 29-05-07 Aligning the elevator hinges,

and hole in fuselage |

29-05-07 Hole is to big, due

to early mistake. I leave it this way, and cover up with the fairing. |

|

|

| 22-05-07 Wow looks like a

plane!!! |

22-05-07 Detail on the wing. |

|

|

| 22-05-07 Tips glued and sanded. (downside) |

22-05-07 Tips glued and

sanded. (downside) |

|

|

| 12-05-07 Vacuum bagging the canard skin |

19-05-07 Forming the canard

tips, cutting away the foam on the edges to fill with epoxy flox. |

|

|

| 08-05-07 Plywood wetting to form the

canard LE!!! |

08-05-07 Plywood drying to

form the canard LE on 22mm tube. |

|

|

| 28-04-07 Elevator vacuum bagging. I put 4

pieces of foam on the M3 ends to protect the bag. |

01-05-07 Elevator sanded and

hinges alligned. Elevator ready for painting!!! |

|

|

| 25-03-07 Elevator foam sanded, I have two

very heavy arms now! |

28-04-07 Elevator vacuum

bagging top skin. The clamps keeps the elevator straight on the table. I

glued the bottom side a few days before. |

|

|

| 24-03-07 Elevator filled with foam |

24-03-07 Elevator filled

with foam both sides! |

|

|

| 18-03-07 Shaping elevator spar, and

glueing first ribs |

18-03-07 Detail on the inner

rib |

|

|

| 13-03-07 Sanding the foam. |

18-03-07 Applied the tips,

and sanded in to shape |

|

|

| 10-03-07 Canard foam glueing. Leading

edge already done |

13-03-07 Canard foam sanded,

tips to go |

|

|

| 10-03-07 Canard foam glueing. Leading

edge already done |

10-03-07 Canard foam glueing.

Leading dege already done. I used an alu angle to align the trailing edge.

Thise alu angle is fixed by the hinge bolts. |

|

|

| 16-02-07 Nutplates ready to glue on the

spar. |

|

|

|

| 16-02-07 Testfit canard on fuselage. I

sanded the bed on 3% |

16-02-07 There is where the

mistake was made!!!!! I forgot the 3% when I traced the hole a few months

ago!. I have to remove the inner construction, and make a new hole :-( . I

dit a test with a heatgun today to heatup a piece of ply with a stick

glued on. I heated it up until the epoxy lost strength. It was a succes,

The ply was ok, and the stick came loose. I will do the same on the

hole inner construction, |

|

|

| 28-03-06 Testfit the hinges on the

trailing edge. Ribs already glued in place. |

18-04-06 Ready to receive

some foam! Sanding of spar and trailing edge done. |

|

|

| 13-03-06 Glued the rib support blocks on

the spar front and back |

14-03-06 Made the ribs today

and testfitting on the spar back. Ribs where made by printing the outline

on paper, glueing the paper on a piece of hardboard, and sanding the board

togetter with 6 pcs of plywood to the printed line. It took me 1 hour to

make 12 half ribs. Planning to make the 2 outer ribs the same way. |

|

|

| canard spar before closing (

tnx Tony) |

closed canard spar and

elevator spar |

|

|

|

|

|

|

|

|

|

|

|

|

|

|