| Engine! |

|

|

|

| 03-01-08 Prophub extender and

back plate |

|

|

|

| 01-10-06 Prop ordered from

Arrowprop in the USA. |

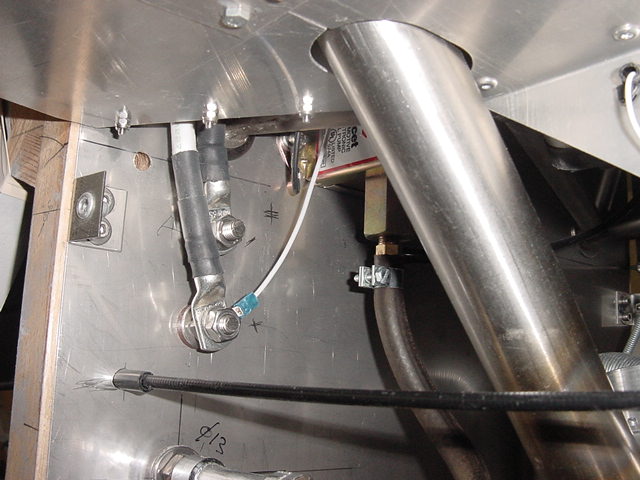

04-08-07 Fuel

valve connected with fuel lines. Now I can close the last fuselage panel. |

|

|

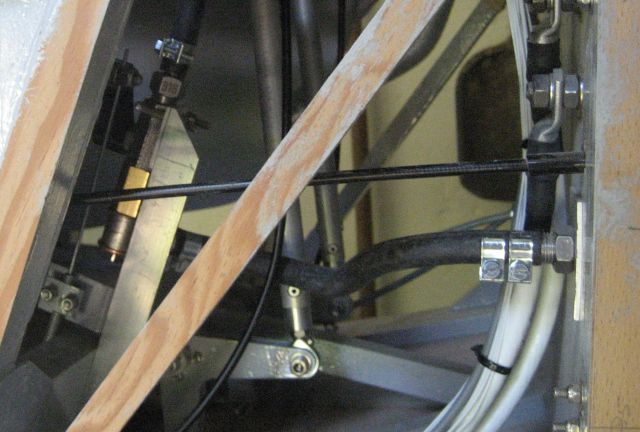

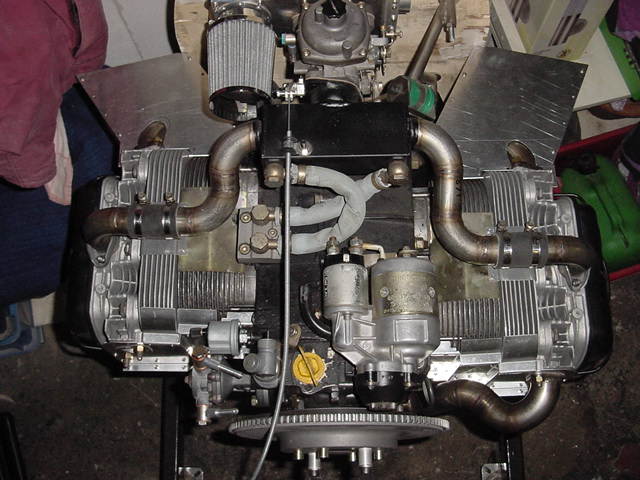

| 24-05-06 Engine installation

ready! view on the wiring |

24-05-06 Engine

installation ready! view on the wiring |

|

|

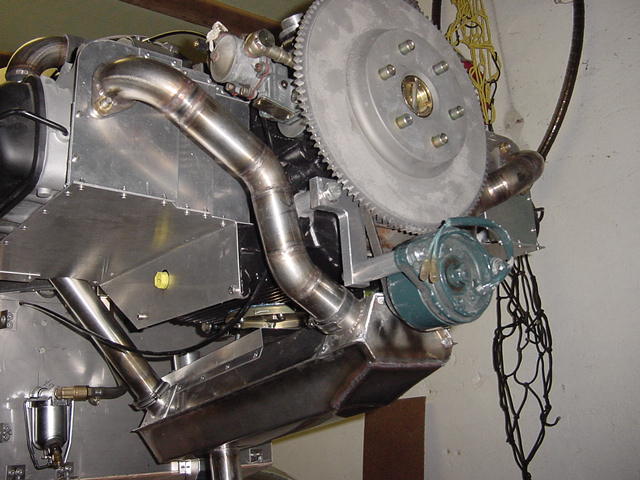

| 24-05-06 Engine installation

ready beside rev pickup, voltage regulator (on order) and some hoses.

Engine was running at first attempt. See short video running |

24-05-06 an

other view of engine installation. |

|

|

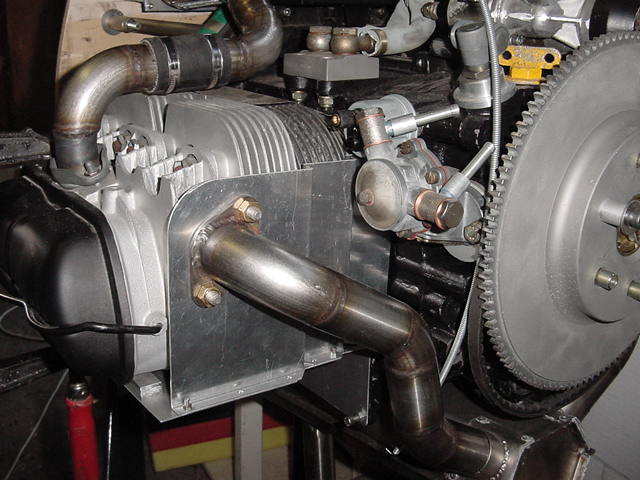

| 29-12-05 Cut the intake

manifold in pieces to make it fit underneath the cowling. Weld it up again

next week. |

02-02-2006

Modified the stack tubes to fit underneeth the cowling. Also cut a piece

off off the damper and made a few changes on the alternator bracket. |

|

|

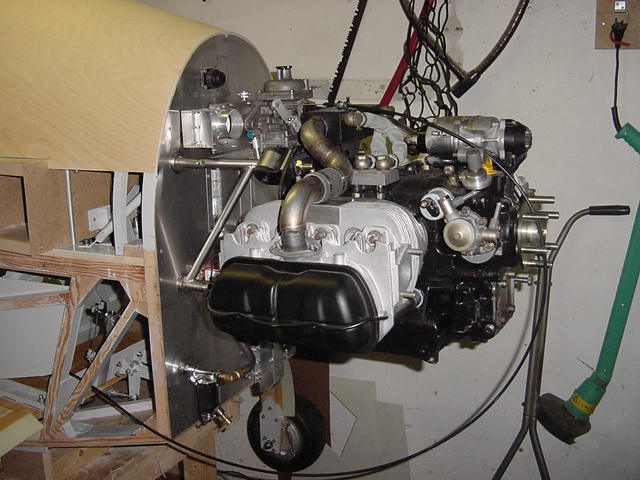

| 08-09-05 Lifting the engine behind the

fuselage |

Engine fixed! Yet put up all

the accesories again |

|

|

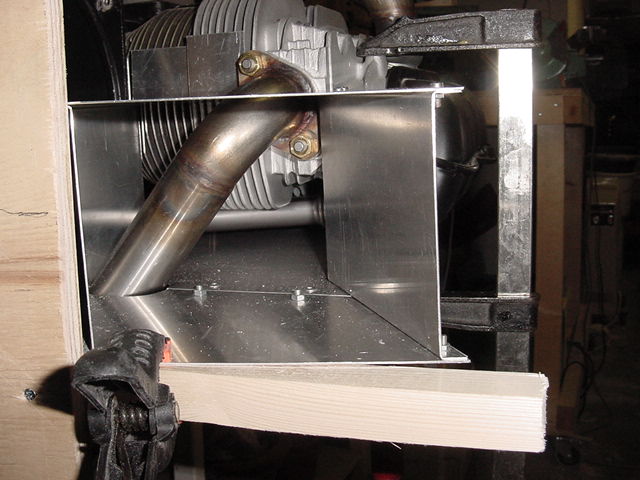

| Inside the cabin heat collector, I wraped

a length of spring round the exhaust pipe to increase the heat

transfer. |

16-8-05 Cabinheat collector

and Carbheat collector. Cabinheat collector is made around the exhaust

pipe, and the Carbheat collector is made ontop of the damper. |

| 12-8-05 Back from holiday ,made the last

pieces on the baffling. There are only a few more things to do on the

engine, -Carbheat collector on exhaust (partly ready), -Cabinheat

collector, -generator bracket, -rev senderbracket (hall type), - some

litle exhaust things ( clamps and springs). After all this I will

put the whole package on the fuselage, put some wiring on and try

a testrun!!!!!!?????????????

|

|

|

| Top view bafling |

Right side top view |

|

|

| 8-7-05 right side bafling,

all work goes quicker now after the left side trial and error! |

12-8-05

Bafling / ducting ready on both sides! Bottom view right side. I do not

use the cowling for the bottomside, but use an extra piece of alu sheet as

seen on JC's IBIS |

|

|

| 5-7-05 frontview of left

side bafling made of 1mm alu sheet. |

5-7-05 rear view |

|

|

| side view. next step is making

the heat collectors for cabin and carburettor. |

5-7-05

Bafling partly done on left side. I made cardboard templates of all parts,

but in alu it is stil different |

|

|

| 03-04-05 Bracket for choke cable and

casing |

12-04-05

exhoust testfit. This is the second damper I made. the first one is messed

up with welding. Now I made flanges, and mounted these with pop rivets and

kit. The box itself is spot welded with similar parts seen below. |

|

|

| 8-1-2005 I made the exhaust pipes of 38mm stainless steel

tube and a cardboard dummy of the damper. Next week I make the real one

out of 0,5mm stainless sheet metal. |

Parts for the exhaust damper |

|

|

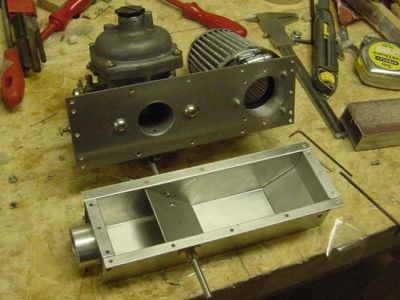

| 30-12-2004 Carb heat box made out of

0,5mm and 2mm alu sheet. |

Heatbox assembled including

intake air filter |

|

|

| Welding jig for intake

manifold-oil cooler. There are 2 welds to make in this jig to position the

cooler. All tube is stainless 35mmx1,5mm. The old intake tubes I sawed off.

Look at www.limflug.de for a 2000EA to

see the original configuration. |

This is how it looks on the

engine. Next step carb heat box |

|

|

| Frontview, ready to

receive flywheel, starter and alternator. |

Sideview. You can

see the lowest bracket is 10mm longer than the top bracket to tilt the

engine a few degrees. The magneto will be mounted on the backside. and the

carb on top.

started to built the exhaust from 38mm

stainless tubing and the inlet manifold / oilcooler from 35mm stainless

tubing. It is not possible to use the standard one, because it will not

fit into the cowling. i will for start not use the oilcooler underneeth

but stay with the Limbach oilcooler. |

|

|

| This is it! 80Hp, 2000cc, from the year 2000!

|

Job is partly done!!

I made an engine teststand with a dummy IBIS firewall. Cilinders, pistons,

head, and oilpump already assembled. The bushes are hold in place with the

green tape. |

|

|

|

|

| This engine mount I

make using stainless16mm tube and lycoming bushes. The bushes are not

installed yet because of the tig welding. The part on the left is a

"trespa" plate with the same footprint as the VW engine. On the

right the firewall of the fuselage. |

This is my litle

powerplant!

a Limbach 2000 built in 2000 (hi). The

engine has run for 1000hr and removed from a Falcke SF25. I flown many

times behind it! Next thing to do is strip it to the bone! and check al

parts. The limbach is actualy an VW type1 with aluminium cillinders (nycasil),

90mm bore and 78mm stroke. rating 80Hp at 3600 rpm 70Hp at 3400rpm.

Carb is a Stromberg CD150 and a Slick magneto. (both not shown)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|