| Mainwing

Started 25-08-07 with first mainwing parts.

|

|

|

|

|

14-12-2009 last part fabricated!!! sanding,

painting and assembly are the only work to do. |

14-12-2009 total weight of the mainwing.

(without vertical stabilizers) |

|

|

|

30 -11-2009 Made the fuel-cap-neck today on the

lathe, and glued in place |

05 -12-2009 Fabricating fairings from wing to

luggage compartiment |

|

|

|

29 -11-2009 fuel sender does not fit beneeth te

luggage compartment floor. I made a hole. later I will cover it.. |

29 -11-2009 workshop overview. to do:

fairings to fuselage, fuelcap. and sanding. In januari the paintshop

has time to spray it. |

|

|

|

28 -11-2009 mainwing to fuselage transision, glued

in place using my fuselage dummy |

29 -11-2009 mainwing to fuselage transision, clamps

are removed. |

|

|

|

20 -11-2009 mainwing to cowling transision |

20 -11-2009 mainwing to cowling transision |

|

|

|

14 -11-2009 bondo applied on starboard upper side |

14 -11-2009 fairings bonded to stabilizer on port

upper side |

|

|

|

13 -11-2009 To flip the wing upside down, we have to turn

it outside the workshop, on the road. |

|

|

|

|

30-10-2009 fairing construction, first tape on the

wood, second bondo in the required shape, third tape again, fourth putting

glass and epoxy on it. afterwards trimming of the part. (front part is

already trimmed) |

30-10-2009 fairing construction, |

|

|

|

30-10-2009 detail on the inspection holes |

30-10-2009 detail on the inspection holes (all are

done) |

|

|

|

30-10-2009 Mainwing is fully covered. I am now bussy with

the trimming of the ply, and all sort of small things. |

30-10-2009 Dummy of my fuselage, and the

attachement of the air-intake (fibreglass) |

|

|

|

20-9-2009 First skin sheet bonded and bag setup for

vacuum |

20-9-2009 Inside pressure 1700 ft! |

|

|

| 24-8-2009 All sanding done!!!!

setting up for skin glueing |

20-9-2009 First skin sheet bonded to the surface |

|

|

| 9-8-2009 Returned from

holiday, with update on current status. Starboard side all foam

glueing is ready. The vertical stabilizer is adjusted and ready for getting

some fearings after the wing is skinned. Now beginning with thw same

work on the port side. |

9-8-2009 Returned from holiday, with update on

current status. Starboard side all foam glueing is ready. The vertical

stabilizer is adjusted and ready for getting some fearings after the wing is

skinned. Now beginning with thw same work on the port side. |

|

|

| 9-8-2009 Returned from

holiday, with update on current status. Starboard side all foam

glueing is ready. The vertical stabilizer is adjusted and ready for getting

some fearings after the wing is skinned. Now beginning with thw same

work on the port side. |

9-8-2009 Returned from holiday, with update on

current status. Starboard side all foam glueing is ready. The vertical

stabilizer is adjusted and ready for getting some fearings after the wing is

skinned. Now beginning with thw same work on the port side. |

|

|

| 6-6-2009 D section all foam

glued in and sanded |

6-6-2009 Start to glue the foam parts in the center

section. all controls has to move free. I desided to glue first the top

sections. |

|

|

| 25-5-2009 It fitted very well

;-) adapted the luggage compartment to the wing and made

the controll rods to the disired length. It realy start to look like a plane. |

29-5-2009 Start to glue the first foam parts. |

|

|

| 21-5-2009 I start cutting the foam. all

leading edge parts done. I made the shape 1mm bigger as the wing shape. this

is sanded off after glueing. |

25-5-2009 I took my wing to the fuselage storage to try

the fit. First it has to travel for 40km on the roof of my car. Hans

Zwakenberg assisted me the whole day, tnx Hans |

|

|

| 21-5-2009 Surface of fueltank filled with

micro and sanded to the wing shape |

21-5-2009 Surface of fueltank filled with micro and

sanded to the wing shape note my simple fuel indicator. |

|

|

| 18-4-2009 Bonded the tank to the spar

with flox and wood shims. |

18-4-2009 Detail on the fixation. (12 in total ). |

|

|

| 10-4-2009 Testfit in the fuselage, all

seems to be within the contours! |

17-4-2009 Test the tank on leakage, used a special leak

tester. I also filled it up with water. It can hold 65 litre |

|

|

|

2-3-2009 Renforcements plates ready, laminating to go |

10-4-2009 Fueltank nearly finished. fuelcap and line

connections to go |

|

|

|

28-2-2009 Outer skin of fuel tank. |

28-2-2009 Back side and the blanks for the reinforcement

on the inside of the tank. |

|

|

| 8-2-2009 Testfit the vertical stabilizer

front section |

8-2-2009 First glass roving cut for tank. laminating

after winter holliday |

|

|

| 1-2-2009 Starting to make the holes for

the hinges. We should see later if they are big enough to mout the ailerons

to the wings |

8-2-2009 Glueing the vertical stabilizer front section |

|

|

| 26-1-2009 Forming the D section. plywood

is drying for one day |

1-2-2009 Both ailerons covered and sanded. |

|

|

| 22-1-2009 Vacuum setup to glue the

aileron skin, sandbags to keep it flat |

26-1-2009 Forming the D section. plywood is drying for

one day |

|

|

| 9-1-2009 Last PS part bonded to the mould.

some sanding and taping to do. see wolfgang's project

http://www.pik-26.de/Bautagebuch_august_2007.html |

22-1-2009 Vacuum setup to glue the aileron skin |

|

|

| 5-1-2009 Made a mdf model of the spar, to

have a base for the mould |

5-1-2009 Overview of the current workshop layout. Wing is

hanging on the ceiling, hotwire setup and PS mould forms clamped together |

|

|

| 3-1-2009 Both ailerons ready for covering |

5-1-2009 I changed plans! Will make a fiberglass fueltank!

Hotwire the first mould parts, and glued together with epoxy |

|

|

| 30-12-2008 Aileron foam glueing. D

section |

30-12-2008 Aileron foam glueing. D section |

|

|

| 27-12-2008 testfit on wing |

27-12-2008 testfit on wing |

|

|

| 20-12-2008 Aileron foam glueing. keep it

straight with a wooden bar |

23-12-2008 D section ribs glued with rubber band

positioning |

|

|

| 20-12-2008 Aileron foam glueing. first

foam on mainwing |

20-12-2008 Aileron foam glueing. detail on rubber bands |

|

|

| 20-10-2008 Nearly all ribs and woodwork

glued to the spar, start rigging the aileron controls and rudder bellcrank |

|

|

|

| 20-10-2008 Nearly all ribs and woodwork

glued to the spar, start rigging the aileron controls and rudder bellcrank |

20-10-2008 Nearly all ribs and woodwork glued to the

spar, start rigging the aileron controls and rudder bellcrank |

|

|

| 31-08-2008 First ribs on main spar,

preparing new ribs |

20-10-2008 Nearly all ribs and woodwork glued to the

spar, start rigging the aileron controls and rudder bellcrank |

|

|

| 31-08-2008 First ribs on main spar. |

31-08-2008 First ribs on main spar, detail on clamping |

|

|

| 13-08-2008 Mating the brackets. some

filing to get it fit. |

13-08-2008 Back from summer

holliday! Started to make the vertical stabilizer connection to the spar |

|

|

| 13-08-2008 Back from summer holliday!

Started to make the vertical stabilizer connection to the spar |

13-08-2008 Back from summer

holliday! Started to make the vertical stabilizer connection to the spar |

|

|

| 07-07-2008 result after closing |

07-07-2008 result after closing |

|

|

| 04-07-2008 Closing the spar reinforcement |

04-07-2008 Did not forget the flapperon control brackets |

|

|

| 02-07-2008 Mating the webs to the spar reinforcement |

02-07-2008 Prepairing the webs. |

|

|

| 21-06-2008 Result! cap in place |

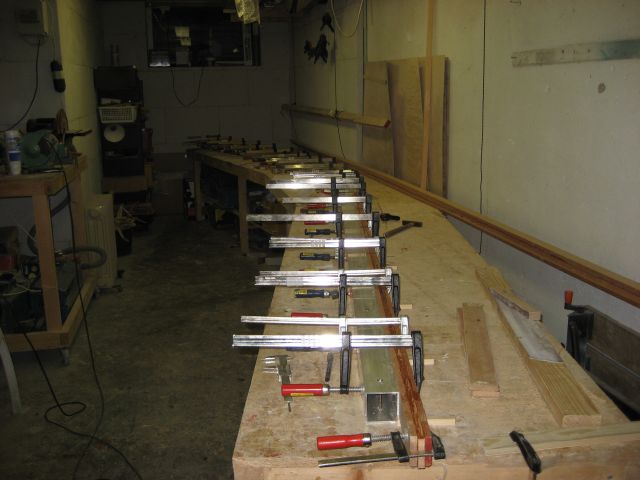

21-06-2008 Closing the mainspar using 65 clamps |

|

|

| 24-05-2008 Setting up mainspar assembly

jig |

24-05-2008 Setting up

mainspar assembly jig |

|

|

| 24-05-2008 Glueing and clamping 45gr

plywood webs |

24-05-2008 Glueing and

clamping 45gr plywood webs |

|

|

| 24-05-2008 Scarfing 45gr plywood webs |

24-05-2008 Glueing and

clamping 45gr plywood webs |

|

|

| 19-04-2008 Planing the caps with my

router. I do not have a planing machine, This takes a lot more time, but

it wil do the job. |

19-04-2008 Planing the caps

with my router. I do not have a planing machine, This takes a lot more

time, but it wil do the job. |

|

|

| 19-04-2008 Also sanded the other side

square, Afterwards I sawed the 2 caps by hand. It took me 4 hours of

sawing. (realy "elbow grease") |

19-04-2008 after 4 hours

sawing, upper and lower cap! |

|

|

| 01-04-2008 Spar glued together, it has

not worked out that well. This is what hapened on one end! I have to

sand it square again. going back to 49mm on the most worse situation.

Leaving only 8mm for planing and sawing |

01-04-2008 Sanding it square

on one side. (other side on the planer) a lot of elbow grease.

Sanding block has only on one halve paper glued to it. Other side is

leaning on the reference tube. The clamps keeping the front side square to

the table. |

|

|

| 18-3-2008 first battens laminated on spar

mold, yes there is some tape on the spacers |

01-04-2008 Spar glued

together, it has not worked out that well. |

|

|

| 9-3-2008 Some finished scarfs. |

18-3-2008 first battens

laminated on spar mold |

|

|

| 9-3-2008 Full size main wing

construction table. I used my old table with an extra angeled center

section. Spar battens lying on top. |

9-3-2008 Sanding the scarf

in spar battens. |

|

|

| 25-08-07 Center section of the fueltank.

cut some alu panels. skipped the fiberglass option. |

25-08-07 Center section of

the fueltank. cut some alu panels. skipped the fiberglass option. (fuel

sender in center) |

|

|

|

|

|

|

|

|

|

|